Considering Transitioning to Vendor Managed Inventory? Read This First!

9/22/2016

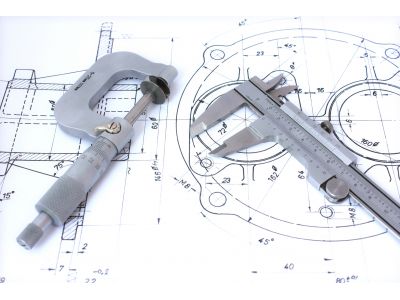

If you’ve been thinking about transitioning your inventory management over to a vendor managed inventory program, you likely have a slew of questions. Does the vendor you’re considering have access to a large number of SKUs? Do they take steps to ensure the quality of the class “C” components that they’re sourcing? Can they adjust stock levels, as needed, as new information comes to light? If these questions were asked of the team at ASF Components, our answer would be a resounding, “yes, absolutely.” In this post, we’re going to look at how our capabilities – and experience – can help you streamline your supply chain and make inventory management a breeze.

Large inventory of SKUs

With the ability to source over 5,700 SKUs, you will never be left waiting for essential parts. Our vendor managed inventory program ensures that you have the parts you need, when you need them.

Optimize your plant

ASF Components can help you reduce your overall inventory by locating underperforming items. In doing this, we can help you increase your manufacturing space, leading to reduced lead times and lower costs.

Effortless communication

One of the biggest factors in slow lead times is communication. When you work with us, you are constantly updated with the most relevant, pertinent information regarding your inventory levels. As a result, you can save money by directing your employees to act upon the information being given to you.

At ASF Components, we pride ourselves on our ability to source a massive number of class “C” components and, even more importantly, being able to deliver them in a timely, reliable fashion. Whether you need fastener nuts, stamping parts or bolts, we have the capability to source exactly what you need and deliver it exactly when you need it. If you’ve been considering VMI, we encourage you to contact us today to discuss your needs.